How to Choose the Right Thermal Protection Solutions

Date: 10/12/25

Thermal protection solutions work to both protect pipes, cables and hoses from external heat sources, and to protect machine operators and nearby equipment from radiant heat from engines and other sources.

Thermal protection is also critical in preventing fires in all kinds of industrial contexts. They provide protection in high temperature environments, such as foundries and steel works, where ambient temperatures are high, as well as protecting from the extreme temperatures of flames or molten splash.

In this article, we’ll take a look at how to select the best thermal protection for your equipment and what to consider when choosing thermal protection products.

Key Factors in Choosing Your Thermal Protection Solution

There is a wide range of thermal protection solutions available, but you can narrow down your choice by applying four simple steps:

Your 4-Step Checklist for Selecting the Right Heat Resistant Sleeve

-

Step 1: Analyse Your Temperature Requirements

Identify the thermal environment your equipment is operating in. Do you need thermal protection from constant temperatures, such as those found in an engine room, protection against occasional temperature peaks, or a combination of both? You need to be precise about your requirements to avoid under-protecting and risking failure, or over-specifying and incurring unnecessary costs.

-

Step 2: Assess the Operating Environment

Does the environment hold any other risks to pipes, wires and hoses, such as mechanical abrasion, chemical exposure, UV damage or damp? Many Sleeve It thermal protection solutions can also protect from these risks.

-

Step 3: Plan the Installation

Ease of installation can avoid costly downtime and disruption. While some companies’ thermal protection products can only be fitted when the equipment is installed, Sleeve It offers hook and loop options that allow upgrades and refurbishments to be retrofitted in situ, without complicated disconnection of equipment.

-

Step 4: Select the Optimal Material

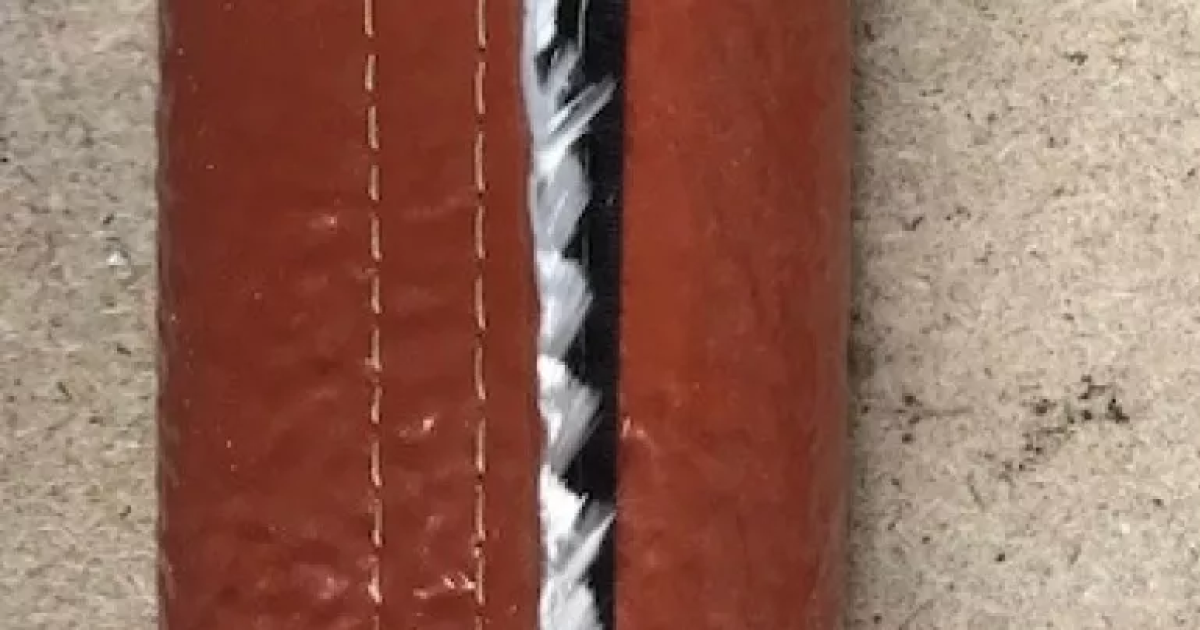

There is a wide range of thermal protection materials on the market, from the knitted E-Glass fibre and high-grade silicone elastomer rubber of Firesleeve to the Basalt fibre of Sleeve It thermal exhaust sleeve. Each has its own distinct properties suited to specific needs.

Common Types of Custom Thermal Protection – match the solution to the application

Once you have assessed the four steps above, you will know exactly what kind of thermal protection you need. There are three main types of thermal protection, and Sleeve It can offer a range of products in each category:

-

High-Temperature Sleeving for Continuous Heat Defence – such as woven E-glass sleeves. Ideal for protecting electrical installations, vehicle electrics and wiring looms from constant radiant heat sources.

-

Protection Against Flame and Molten Splash – such as silicone coated sleeves. Ideal to protect against sources of direct flame or molten splash, as well as protect from chemical exposure.

-

Reflective Heat Shields and Wraps – such as aluminium glass laminate sleeves. Ideal for protecting parts in close proximity to heat sources such as engines and exhausts.

Expert advice always on hand

If the process for selecting your thermal protection solution feels complex and confusing, don’t worry, because help is always on hand.

Sleeve It offers a comprehensive range of thermal protection products, and our expert team will be happy to help you identify and specify exactly the right products for you. Simply work your way through the four-step process above and then get in touch to see which product best suits the needs you have identified.

Whichever you choose, you’ll get next day delivery across the UK on in-stock orders placed before 3 pm.

Protect your equipment simply and cost-effectively with Sleeve It

Choosing the right custom thermal protection solutions often comes down to choosing the right supplier – and with Sleeve It, you’ll find everything you need, from a comprehensive range to incomparable service.

To discuss the best thermal protection products for your next project, contact our team today, because when the heat is on, Sleeve It protection can be priceless.

Frequently Asked Questions

It depends on the temperature you are operating at. The woven E-glass fibre of Firesleeve thermal protection sleeving resists constant temperatures of up to 260°C and molten splash of 1200°C, while the Basalt fibre of Thermal Exhaust Sleeve protects at a constant temperature of up to 750°C.

A heat sleeve protects against ambient temperatures, such as those found in engine bays. A fire sleeve has added protection against direct flames and molten splash, forming a protective layer that resists further fire damage.

The woven E-glass fibre core of Firesleeve is coated in a high-grade silicone elastomer rubber. This melts on contact with direct flame, creating a strong silicone dioxide layer that resists flame and protects the cables, pipes and hoses within.

Yes. At Sleeve It, you can get thermal protection products cut to length for ease of installation and waste reduction. Firesleeve is available in a choice of 32 diameters, from 4mm to 203mm, to suit all kinds of applications.

0 Comment

Add your Comment

We have the ability to edit and/or delete posts and comments. Links should be relevant to the topics. Please note all comments are subject to review before inclusion.

Nobody has commented yet. Why not add one?